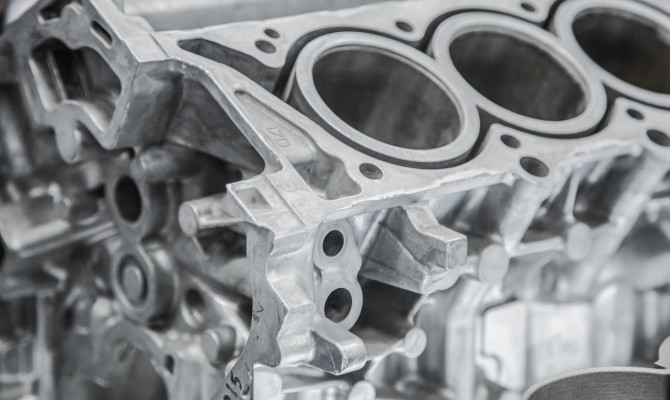

Die casting

Products & services

→-

Injection system components

-

Plungers

-

Die components

-

Monitoring software