55% cycle time reduction with iTherm® Core

55%

shorter cycle time

Background information

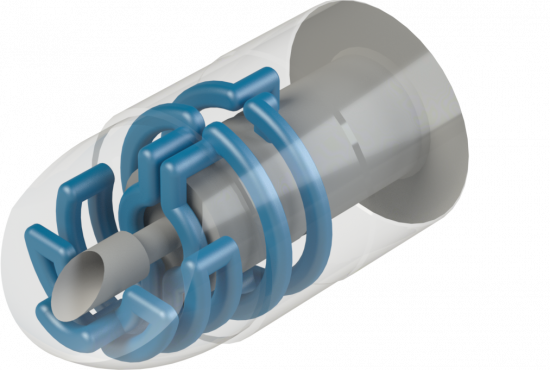

Our customer that produces thick wall plastic piping was struggling with cycle times when moulding 90° pipe elbows.

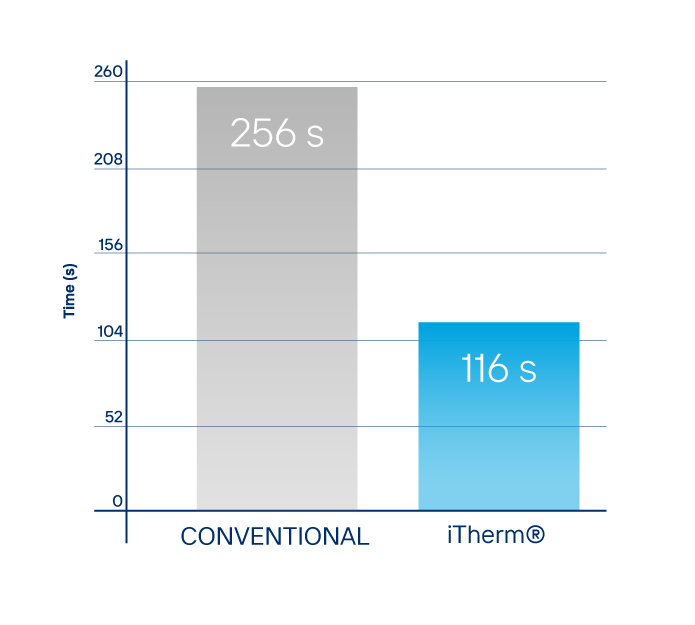

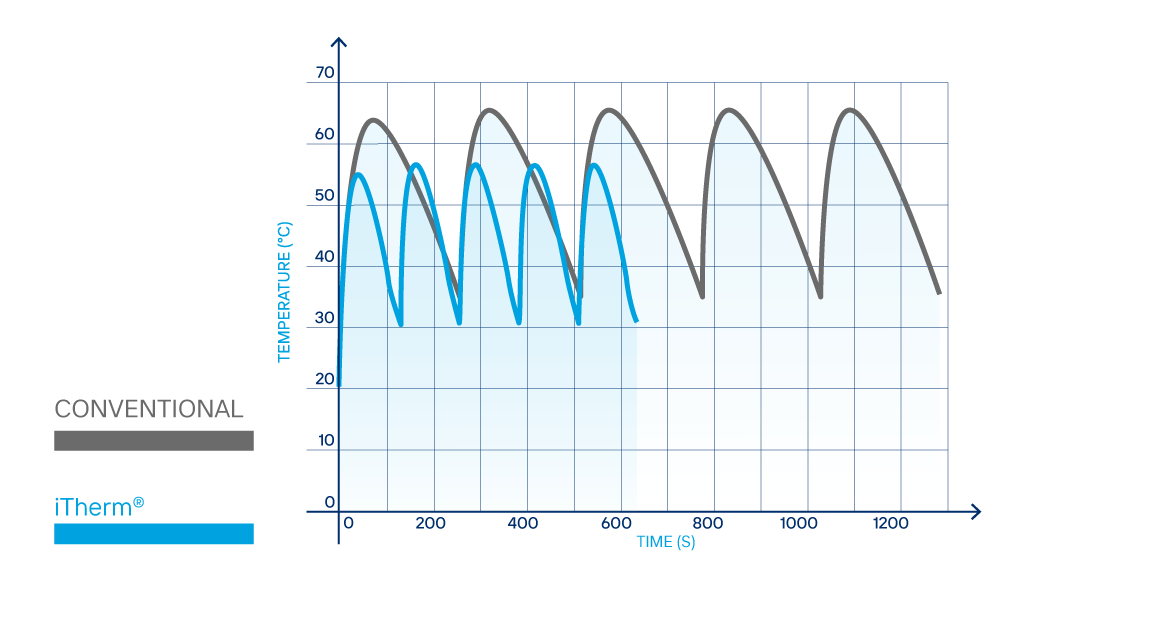

Their cycle time was 256 seconds.

FEA analysis that has been carried out predicted a massive cycle time reduction to 125 seconds (graph below).

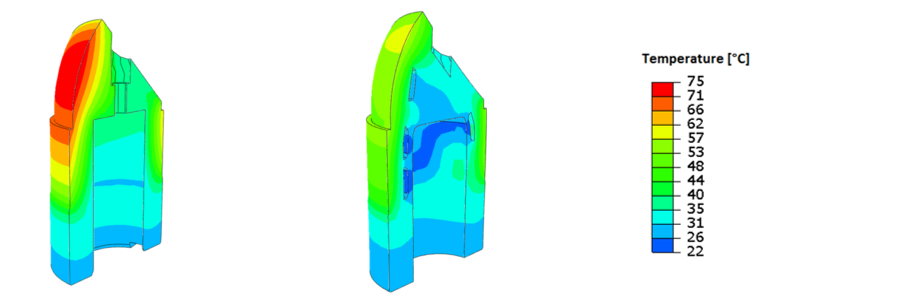

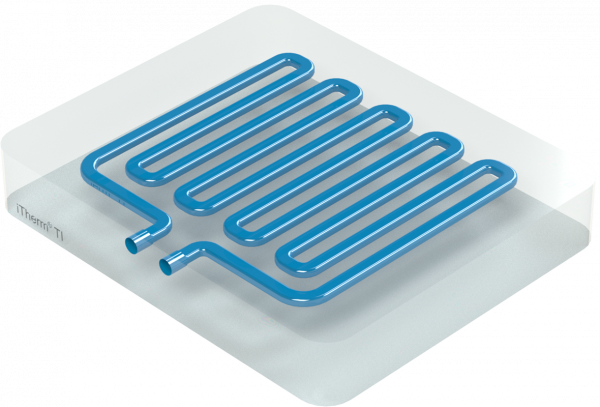

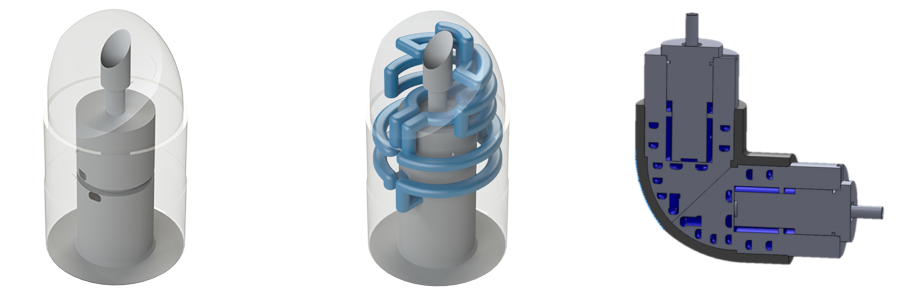

Based on big potential savings customer decided to replace its current core (left image) with a conformally cooled iTherm® Core.

Improvements with iTherm® custom Core

More uniform heat distribution across the work surface