59% shot sleeve cost reduction using HTS innoSleeve insert

Our EU-based customer that produces castings for the automotive industry was trying to increase the lifetime of shot sleeves. Conventional 1.2343 / H11 shot sleeves without thermal regulation had an average in-service lifetime of app. 30.000 shots.

59%

cost reduction

BACKROUND

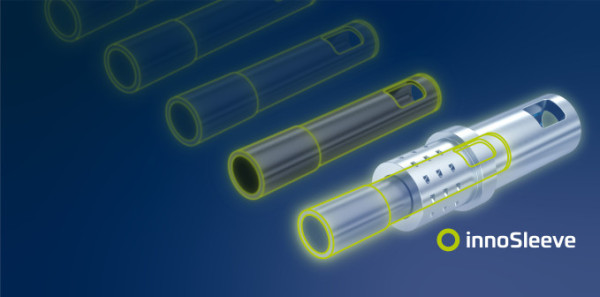

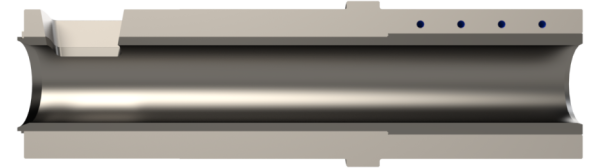

Based on HTS proposal, they have decided to test HTS innoSleeve insert with thermoregulated envelope, made with our specially developed alloy to decrease the costs of the sleeve and also to extend the number of shots during sleeve replacements.

Type of Shot sleeve used before

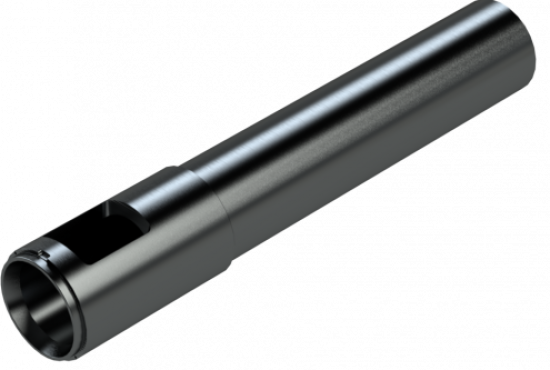

HTS Envelope with innoSleeve Insert

Improvements with innoSleeve

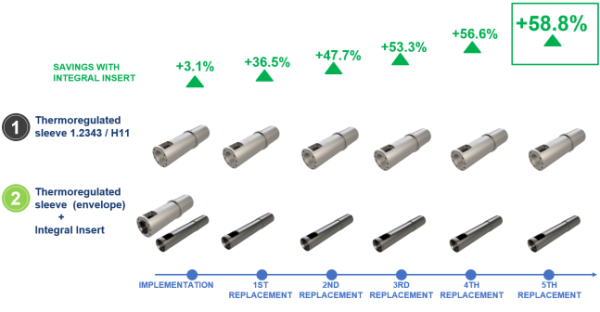

They have been comparing the costs of two specific dimension sleeves, Ø140 x Ø340 x L1006 and Ø170 x Ø349 x L1002.

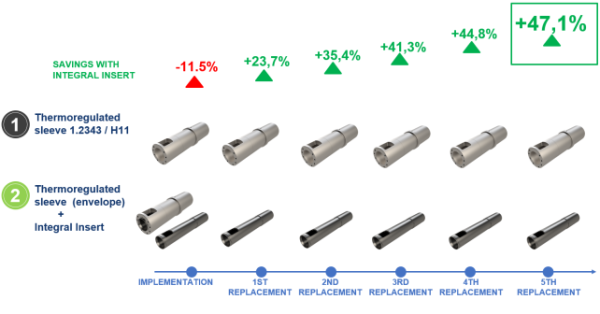

In case of Ø140 sleeve, the initial investment into envelope and integral insert / liner was 11,5% higher, however already at the first replacement they saved more than 23%. By the time of 5th replacement, cost of HTS provided solution was 47% lower compared to conventional shot sleeve.

Ø170 sleeve could be re-machined, so the initial investment was lower and 3% savings were recorded already in the implementation phase. By the time of the 5th replacement, the cost of the HTS-provided solution was 59% lower compared to the conventional shot sleeve.