Endura B Plunger

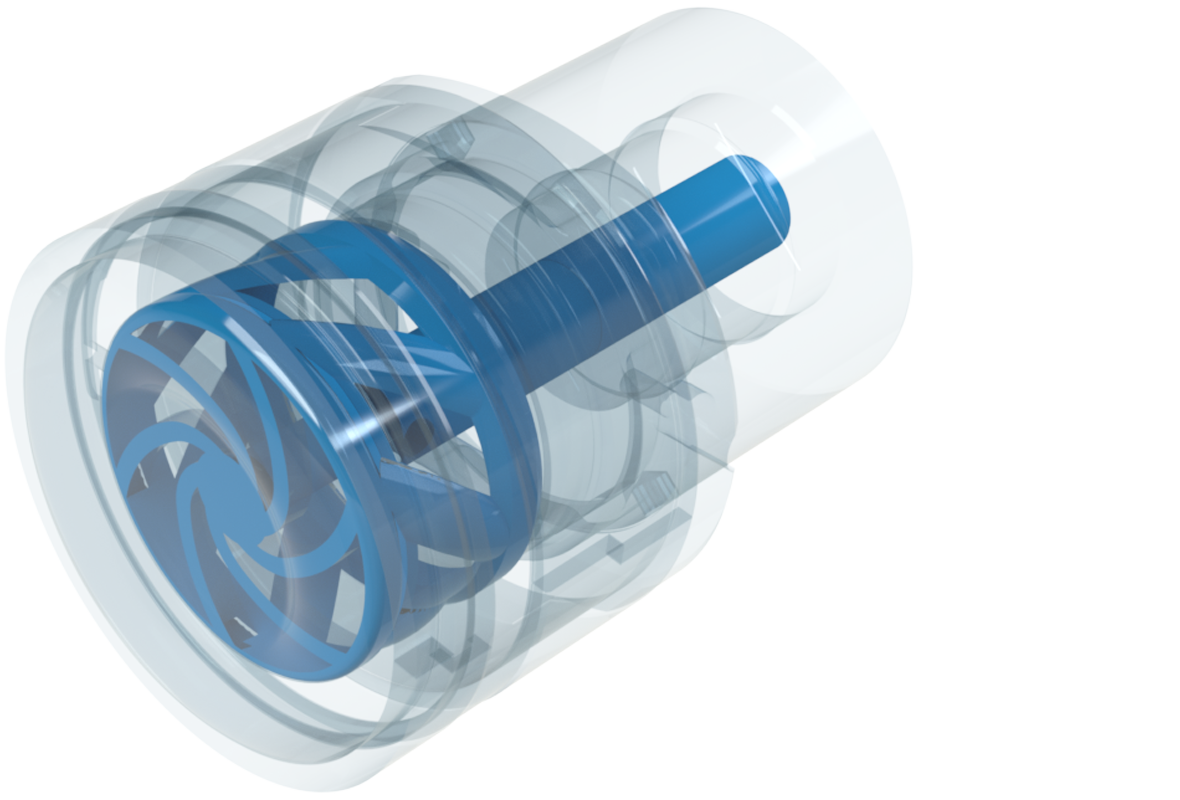

Endura B is a patented plunger with a special design and cooling channel configuration that ensure optimal cooling during the injection process.

It is produced using high-strength hot work steel.

The plunger is fixed to its holder by our special bayonet locking design.

Endura B plunger is provided with a frontal ring creating an optimal sealing between sleeve and plunger and a spring bush (back ring) specially designed for vacuum application.

Endura B Plunger is available in 2 versions depending on casting process and application:

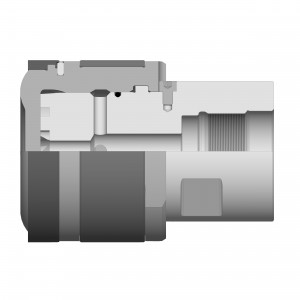

Endura B-RS: Standard version with frontal and spring bush.

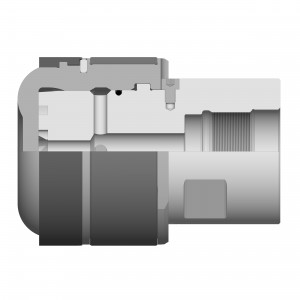

Endura B-RS/BN: Bullet nose version with frontal ring and spring bush.

HTS DIFFERENCE

Advantages over conventional plunger

Assembly allows minor misalignment

In comparison with a conventional lock system between plunger and holder, the coupling is done using a special bayonet system. This one provides a small functional play between both holder and plunger, compensating for small misalignments.

Cycle time reduction

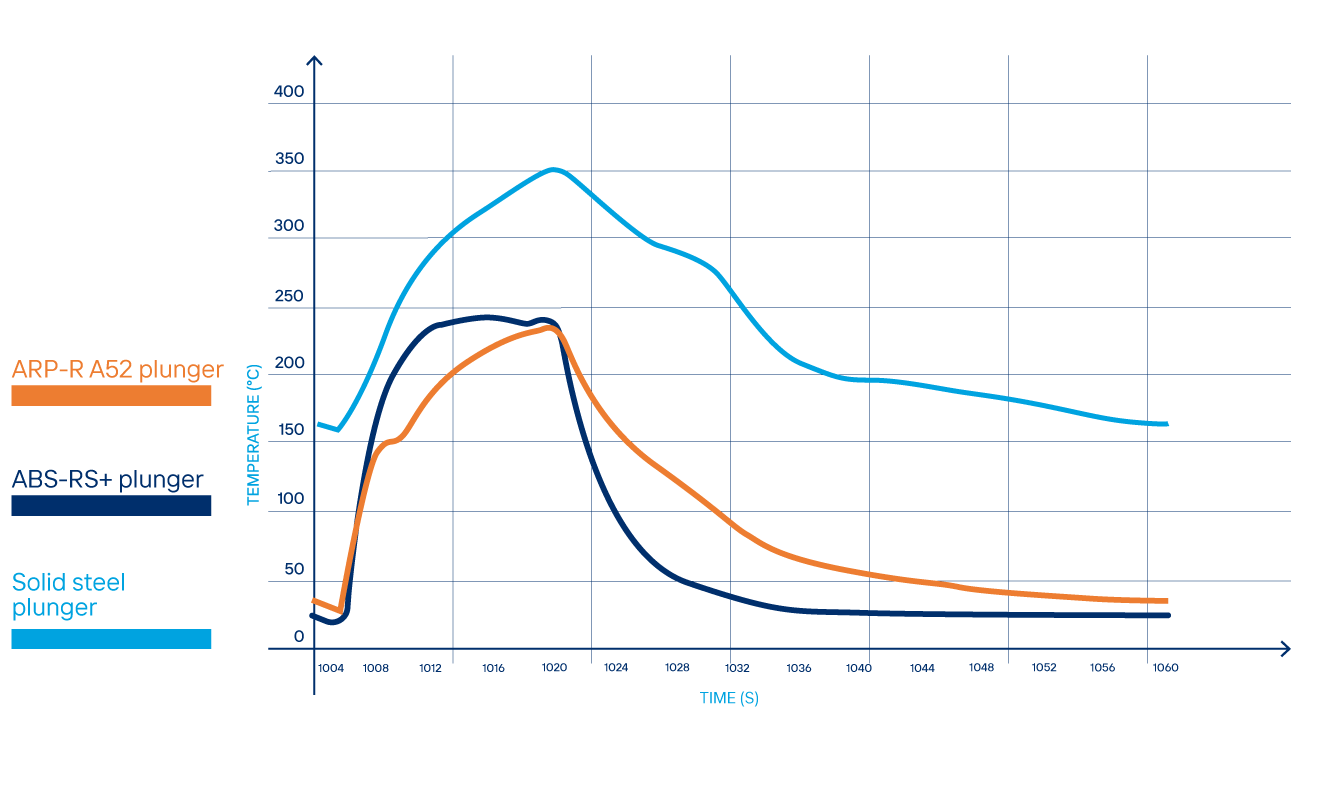

Compared with a conventionally made plunger, the cooling arrangement is optimized, resulting in more efficient and homogenous cooling and solidification of the biscuit.

Assembly and removal of the ring are straightforward and can be done directly on the machine, avoiding any waste of time.

Longer lifetime

The assembly of the Endura B plunger with its holder has been specially designed: the holder itself rests against the inner surface of the plunger absorbing the total injection pressure and avoiding cracks and fatigue.

Endura B plunger achieves a longer lifetime compared to copper-made plungers because of less dilatation. Copper dilatation equals 17-6, while in the case of high-strength hot work steel, the expansion is up to 11-6.

PLUNGER COMPARISON

PARAMETERS

Dimensional range

Diameter 50 - 230 mm (2.00" - 9.00")

MATERIAL

Endura B-RS plungers are made using forged or rolled tool steel bars produced in EU.

Plunger rings

We manufacture a selection of plunger rings and spring bushes for Endura B plungers. Read more…