innoSleeve liner

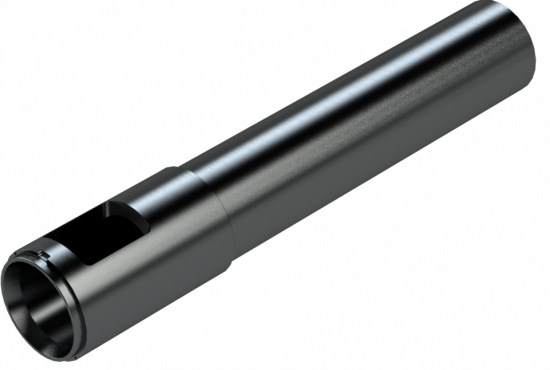

Integral Insert/liner is a special component used to protect the innoSleeve across the complete diameter and length.

It is a single body component produced using our specially developed wear-resistant alloy.

It is easily inserted and replaced in the sleeve with our custom made tool.

It is highly customizable to specific customer requirements.

In majority of cases the existing conventional shot sleeves can be transformed into innoSleeve to accommodate the integral insert. The transformation does not influence the outer diameter of the sleeve.

HTS DIFFERENCE

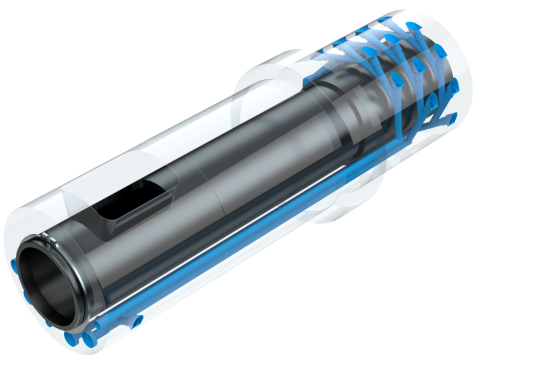

HOW INNOSLEEVE WITH INTEGRAL LINER WORKS

After the innoSleeve is bored to form an envelope, a special integral insert/liner that covers the complete length of the innoSleeve gets inserted into the envelope

This way innoSleeve envelope never comes into direct contact with molten alloy, so sleeve replacements are completely avoided. Insert/liner is the only component that needs to be replaced

Insert/liner gets replaced very quickly. In the case of smaller machines, it can be done directly on the machine, while in the case of larger ones, there is a special replacement tool we provide.

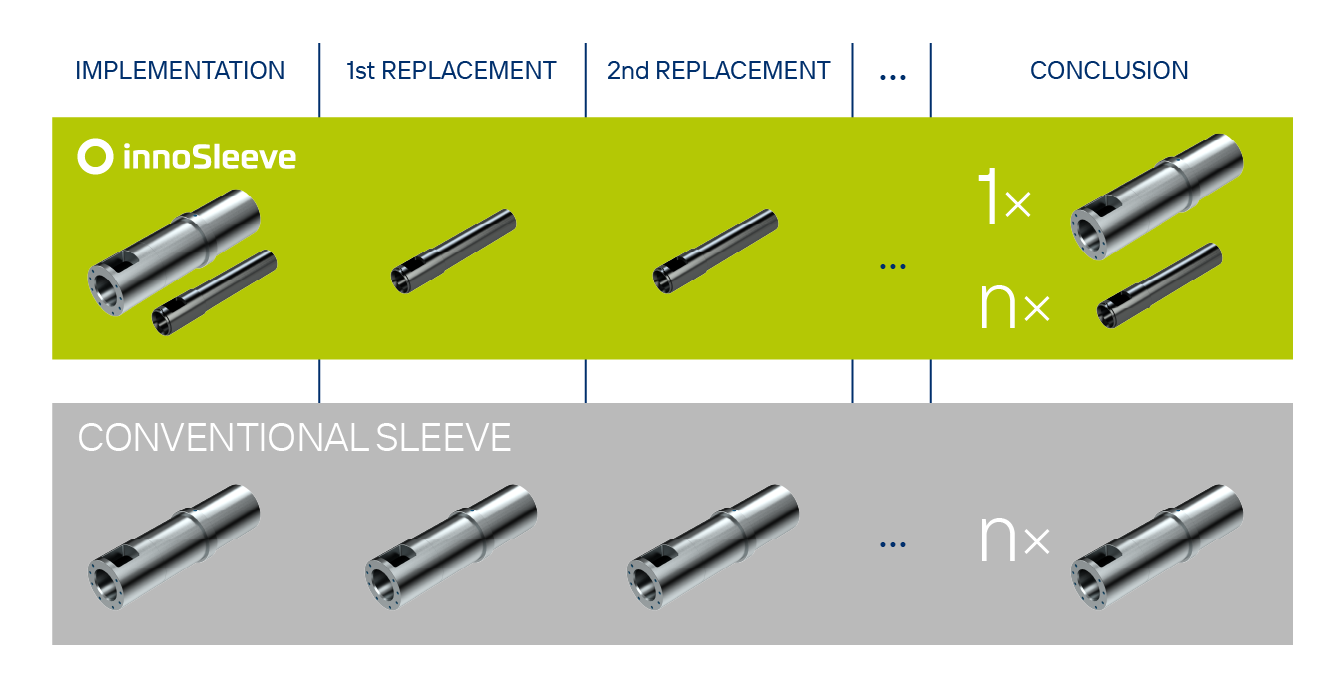

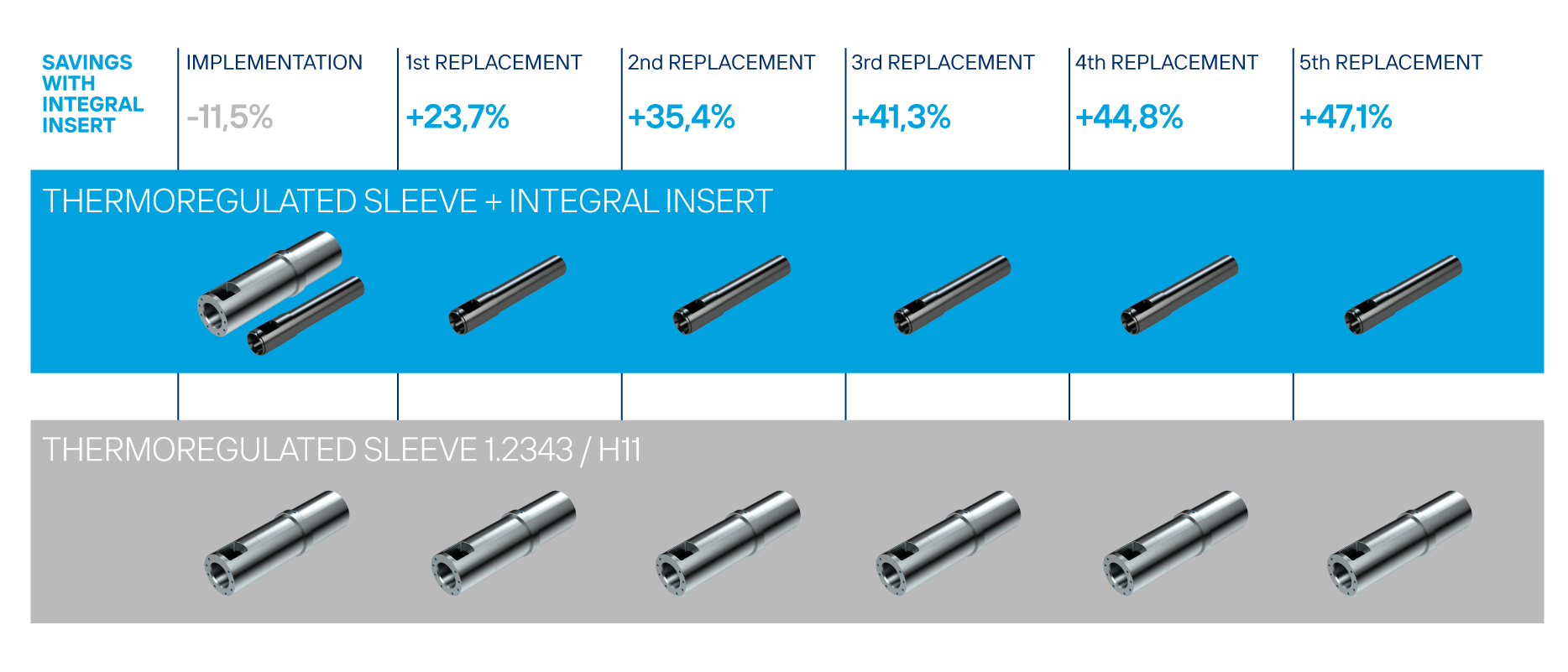

When using the innoSleeve, the cost of the envelope occurs only at the start of implementation, while for each next replacement only the integral Insert/liner is purchased.

As seen on the image below, the difference in usage compared to conventional shot sleeves is that with innoSleeve the cost of the envelope occurs only once, at the implementation and after that, for each replacement, only the itegral insert/liner needs to be changed with a new one, while envelope remains unchanged.

Advantages of using innoSleeve with integral liner

Longer in-service lifetime

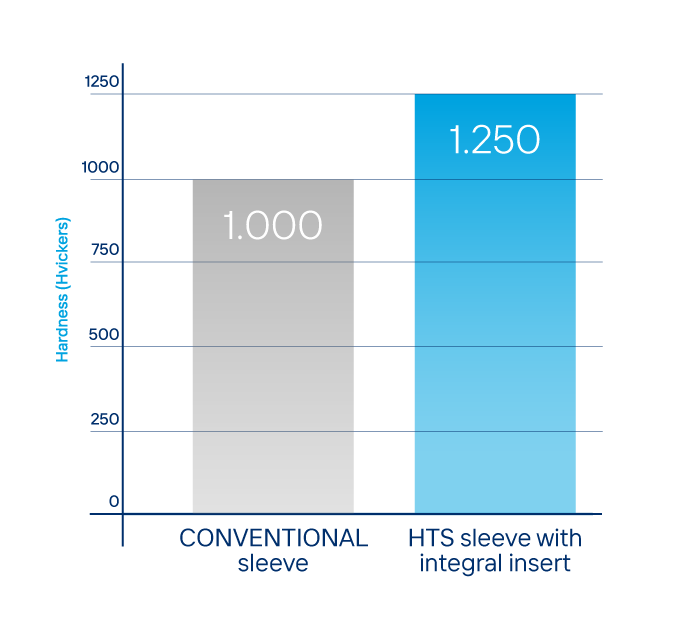

innoSleeve Integral Insert / Liner is made using the specially developed alloy that allows us to bring nitration layer hardness up to 1.250 Hvickers. This is 25% more than what can be reached when using traditional 1.2243/H11 or 1.2344/H13 made shot sleeves. Such difference in hardness translates into a substantially (up to 55%) longer lifetime than the conventional sleeve.

Lower costs

Using an Integral insert/liner to protect the shot sleeve you save up to 30% on the cost of sleeves, because the amount of sleeves required to complete a series is reduced substantially. In some specific cases, savings can reach up to 60%. Below is a case of customer savings on Ø140 x Ø340 x L1006 sleeve.

PARAMETERS

Dimensional range

Inner diameter 2 - 9 ¹/₁₆ inch (50 - 230 mm)

Length 8 - 63 inch (200 - 1.600 mm)

Mounting options

Based on the type of the sleeve, different mounting options can be used

-

cap

-

clamps

-

seeger ring

Material

Integral inserts can be made of three different material choices, 1.2343 / 1.2344 or by using one of the two specially developed tool steel grades.

Delivery condition

heat treated

hardness between 42 and 50 HRC

machined to final dimension

nitrided