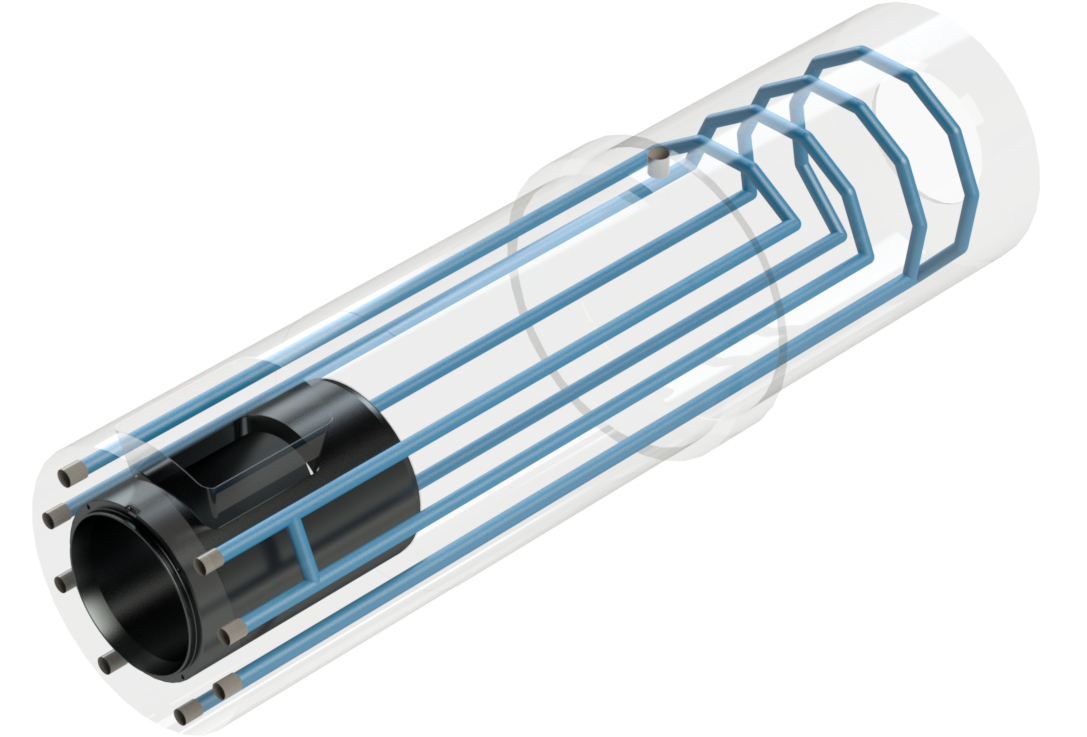

Replaceable Insert / Liner

Replaceable insert is produced using tool steel forged or rolled blocks.

It is a standard dimensions component compatible with all shot sleeves.

It is used in cases when the sleeve in the pouring zone is exposed to severe operating conditions.

HTS DIFFERENCE

Advantages of using replaceable insert

Extended sleeve lifetime

One sleeve can on average last for 3 insert replacements before it has to be replaced. This way sleeve in-service time is substantially prolonged.

Lower operating costs

Using replaceable inserts, the number of sleeves required to complete a series is lower than in cases when inserts are not used. This results in lower expenditure on shot sleeves.

PARAMETERS

Dimensional range

Inner diameter 2 - 9 ¹/₁₆ inch (50 - 230 mm)

Length 6 - 14 inch (150 - 360 mm)

Mounting options

Based on the type of the sleeve, different mounting options can be used

-

cap

-

clamps

-

seeger ring

Material

Replaceable inserts are made using forged or rolled tool steel blocks produced in EU.

Most often used grades are, special HTS developed alloy or 1.2343/H11.

Based on specific customer need, other steel grades can be used.

Delivery condition

heat treated

hardness between 44 and 48 HRC

machined to final dimension

nitrided