HTS brands

Our brand promise is the sum of who we are, what we believe in and the reason we exist. It is what we strive to deliver every day within our company and to our customers.

Building blocks of our brand

We have identified four strategic areas as the building blocks of our brand promise and position. Being in the forefront with each of them is what makes us unique today and will so in the future.

OUR BRANDS

We have designed the HTS brand architecture to explain our unique position, and to be as clear as possible to our business partners and colleagues.

CORPORATE BRAND

HTS International is our corporate brand, representing a unique combination of advanced manufacturing technologies, intensive R&D and customer technical support. We bring together the know-how and experience of in-house production processes, from cutting the steel to machining, heat treatment to advanced additive manufacturing processes.

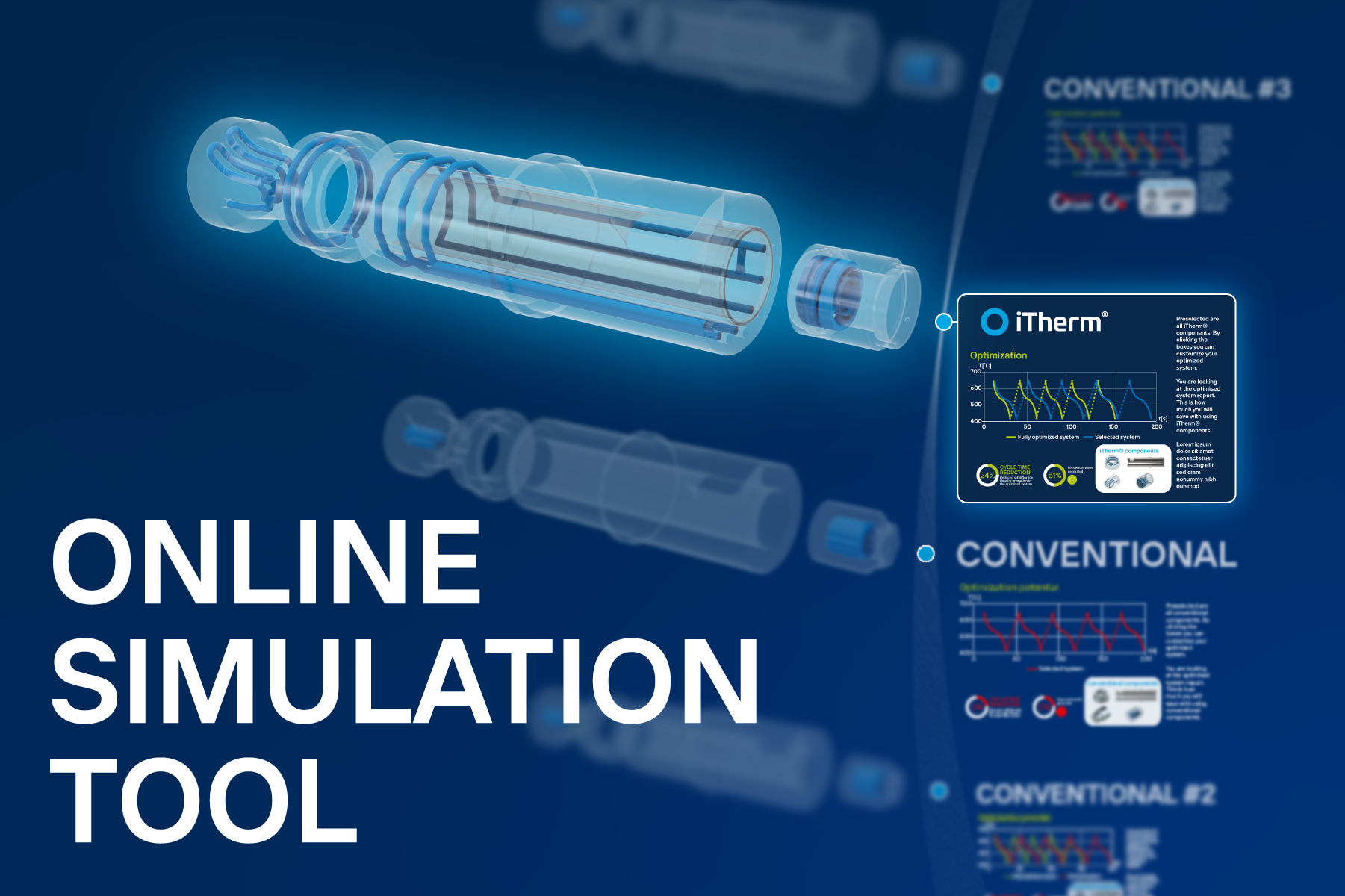

iTherm® PRODUCT BRAND

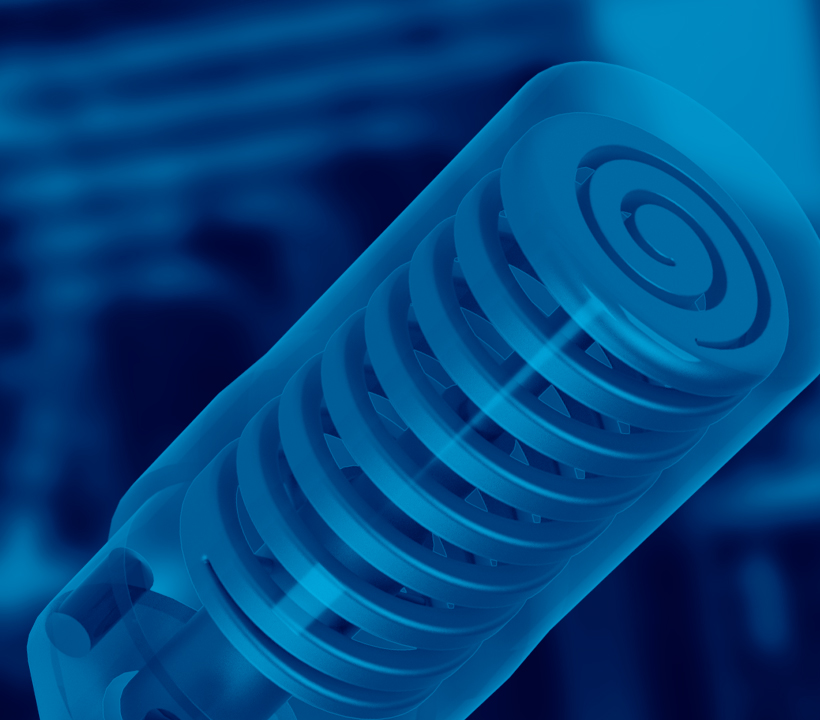

iTherm® brand stands for ultimate productivity solutions, based on principles of conformal cooling. iTherm® components are made using different additive manufacturing technologies, among which also MFT, our proprietary metal fusion technology.

iTherm® is not only a brand but also a promise, a promise of superior thermal management possibilities and unrivalled component performance.

iTherm® products are used in industries where effective thermal management of components is essential for productivity and quality. Below is an overview of iTherm® product range.

iTherm® conformal design components are used in environments where effective thermal management determines productivity. Conformal design can also be applied for material flow optimization. These are some examples of iTherm® components used in high-pressure die casting and injection moulding industries.

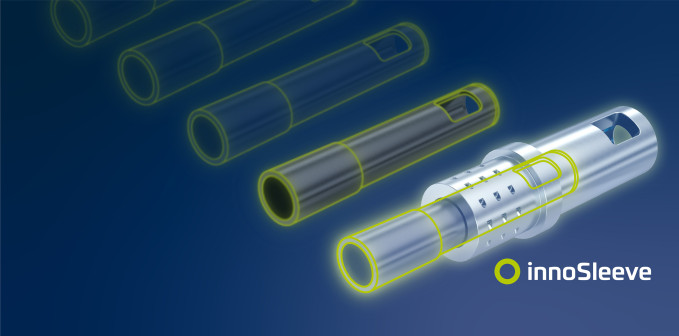

innoSleeve PRODUCT BRAND

innoSleeve brand manifests our commitment to reducing the CO2 footprint generated during the shot sleeve production process.

As the name indicates, this is an innovative product that pushes the environmental and cost efficiencies of regular sleeves to a higher level. In contrast with other HTS product brands, innoSleeve sign is coloured green, additionally emphasizing its orientation towards a more sustainable future for our industry.

By implementing innoSleeve in their foundries, our customers also signal their commitment to, and support of, a more sustainable supply chain.

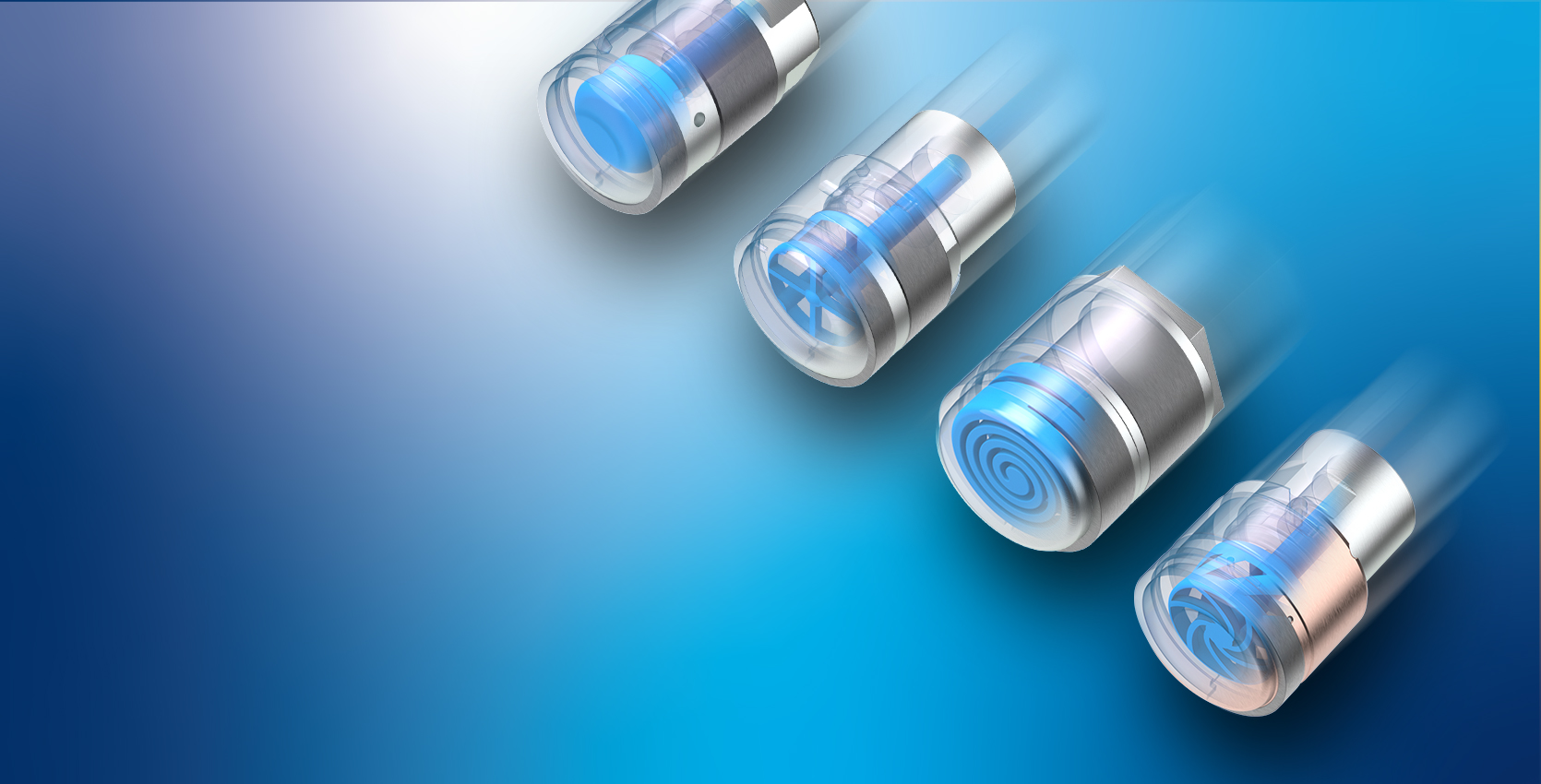

Plunger PRODUCT BRAND

The brand Plunger by HTS has been introduced to consolidate our extensive range of plungers, which is recognized as the most comprehensive in the industry. Plunger by HTS brings together three distinct sub-brands: Plunger Conducta, Plunger Endura, and Plunger Performa. Each sub-brand offers innovative plungers designed to cater to a diverse array of applications, showcasing cutting-edge technology and superior performance.

By unifying our plunger range under the Plunger by HTS brand, we reaffirm our commitment to providing customers with the highest-quality solutions that meet their diverse needs. Whether it's precision, durability, or performance, Plunger by HTS offers a comprehensive range of plungers that deliver unmatched reliability and efficiency in the most demanding applications.