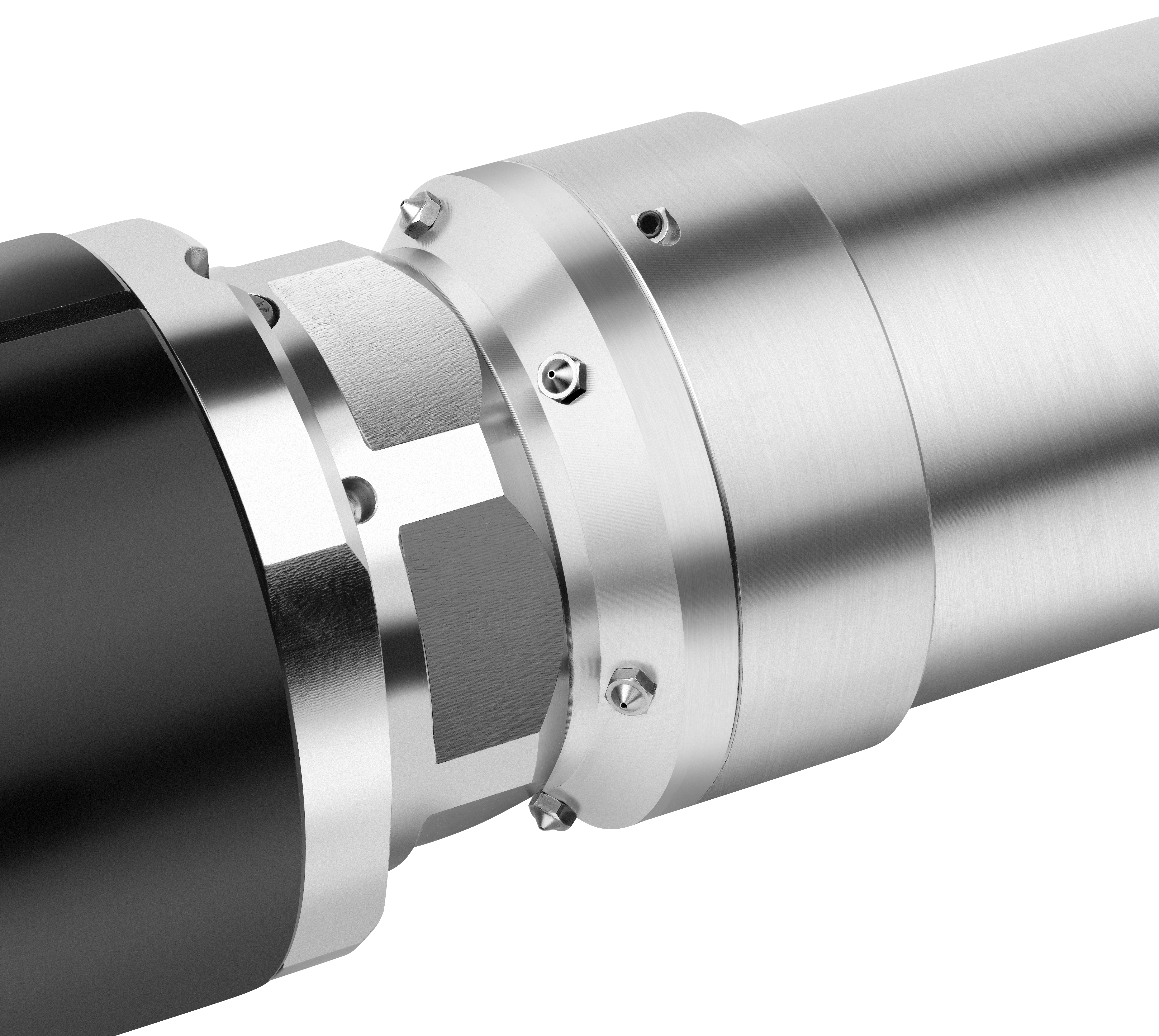

Uniform lubrication of complete sleeve area

As the sleeve is lubricated through the spray ring at the end of the plunger rod, the lubricant is applied throughout the whole length and diameter of the sleeve.

Less lubricant consumption

Due to more even distribution, it uses less lubricant than the commonly used lubrication methods. Using less lubricant, fewer impurities are brought to the cast product, resulting in higher cast product quality.

Less production downtime

By lubricating the sleeve throughout the whole length and diameter, wear of sleeve and plunger is reduced, prolonging their lifetime. This is directly reflected in less production downtime and improved casting process stability.