iTherm® Sprue bushing

iTherm® Sprue Bushing is produced using tool steel forged or rolled blocks and HTS proprietary additive manufacturing technology.

It is a single body component with equal mechanical properties as tool steel monoblock.

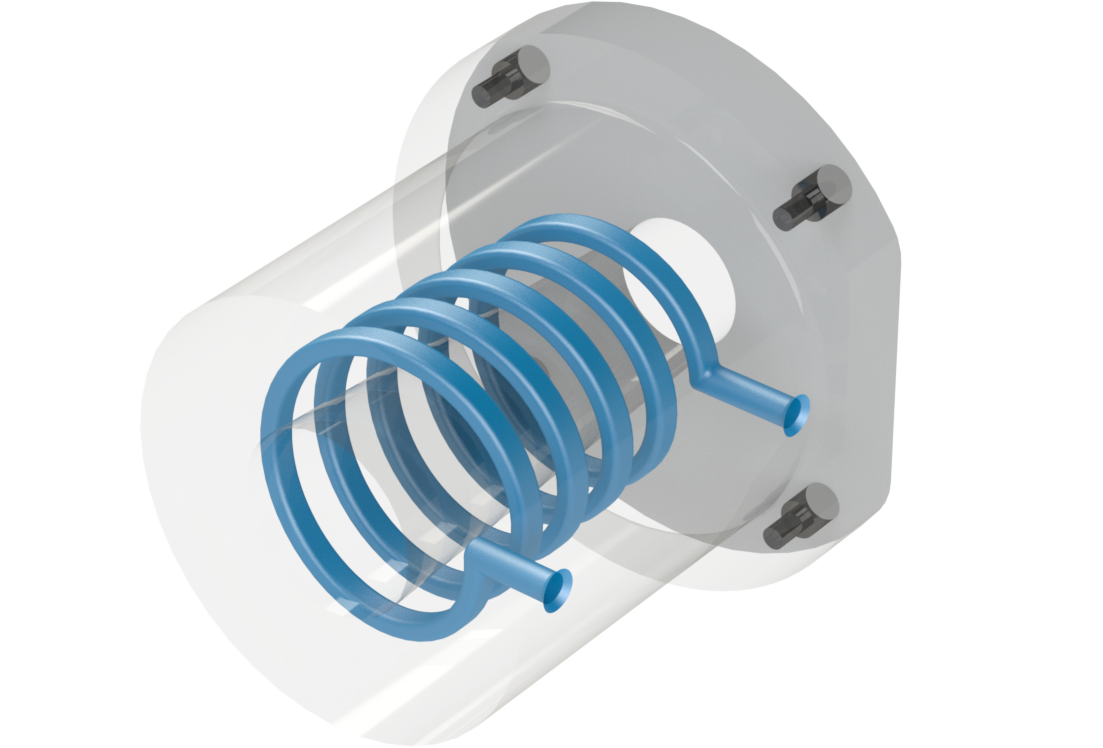

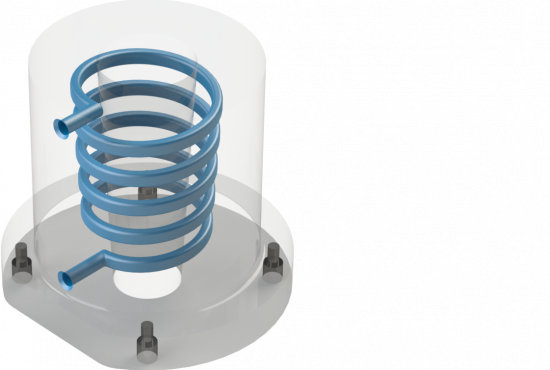

Cooling channels can be freely designed according to the cooling/heating requirements of the product, not by the limitations of using the conventional drilling method.

It is highly customizable to specific customer requirements.

HTS DIFFERENCE

Advantages over conventional sprue

More freedom designing cooling channels

In comparison with conventionally made sprue bushing, iTherm® Sprue bushing gives you extra flexibility to bring cooling channels near the critical zones of the sprue.

Faster sprue bushing cooling rate

In comparison with conventionally made sprue bushing, using iTherm® Sprue bushing, the heat is distributed much more evenly over the surface, so the sprue is cooling down more evenly and quicker.

Cycle time reduction

Combining the advantages of iTherm® Sprue bushing you can significantly shorten cycle time. Our customers have reported up to 25% shorter cycle times on dies limited by sprue cooling when replacing conventional sprue with iTherm® sprue.

PARAMETERS

Cooling power

Between 10 and 30 W/cm2 of heat extraction.

Dimensional range

Diameter 5 ¹/₈ - 8 ¹⁷/₆₄ inch (130 - 210 mm)

Height 4 ²¹/₆₄ - 7 ³¹/₆₄ inch (110 - 190 mm)

MATERIAL

iTherm® Sprue Bushings are made using forged or rolled tool steel blocks produced in EU.

Most often used grades are 1.2343/H11, 1.2344/H13, 1.2367, Uddeholm Dievar.

Based on specific customer need, other steel grades can be used.

Delivery condition

heat treated

hardness between 42 and 48 HRC

machined to final dimension

nitrided