How To Extend Sleeve Lifetime Cost Effectively

Shot sleeve function is to hold molten aluminium while its being pushed into the die by the plunger. Usually, it’s made using various types of hot work-tool steels, ranging from 1.2343/H11, 1.2344/H13 to 1.2367, and nitrided to ensure wear resistance.

Casting process wise it is important that plunger consistently moves through the sleeve, while seal between the shot sleeve and the plunger is ensured.

With constant temperature changes and components’ thermal expansion during casting cycle, the gap between the plunger and the sleeve is changing and in cases when it surpasses 0.1mm, the molten aluminum can flow by, form a compound and cause additional wear on both, the sleeve and the plunger. This results in extensive wear, premature failure and unplanned production stoppages.

55 %

Up to 55% longer lifetime

Effective management of the gap between the sleeve and the plunger mainly comes down to two areas, good thermal management of sleeve and plunger, and dimensional stability of the sleeve.

Below we discuss how to ensure maximum dimensional stability of the sleeve to assure optimal cost efficiency.

Sleeve warpage

At the beginning of the casting cycle, in the pouring phase, molten aluminium reaches temperatures between 650 and 700 °C and when it touches the bottom part of the sleeve, the thermal load is the highest and sleeve temperature can surpass 400°C. As aluminium only touches the bottom part of the sleeve at this point, the difference in temperatures between the bottom and top part of the sleeve in the area of the pouring hole can reach up to 150°C.

Sleeve temperatures in pouring phase

Such temperature difference leads to uneven thermal expansion in different areas of the sleeve. Over time, sleeve geometry gets distorted so it can become slightly oval instead of round or bowed through its length. This effect is also known as sleeve warpage, ski or banana effect.

The majority of die casting companies are facing the same challenge, wanting to maximize the lifespan of the sleeve and to ensure best dimensional stability throughout its operation while bringing down the costs.

HTS SOLUTIONS

Replaceable insert

Replaceable insert is used to protect the sleeve in the back, under the pouring hole, where the thermal load is the highest, especially in cases when erosion is the main problem. There are different kinds of inserts available nowadays, solid inserts, split inserts, tungsten inserts, etc...

The main challenge when using a replaceable insert is, that the front part of the sleeve gets worn out by aluminium throughout the operation, so precisely placing the inserts, gets more and more difficult with each insert replacement. Using a replaceable insert doesn’t eliminate the need to replace the sleeve eventually, but it does lower the sleeve change frequency.

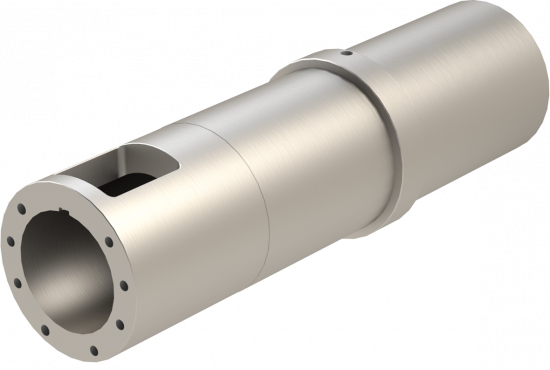

Shot Sleeve with replaceable back insert

Thermoregulated Sleeve

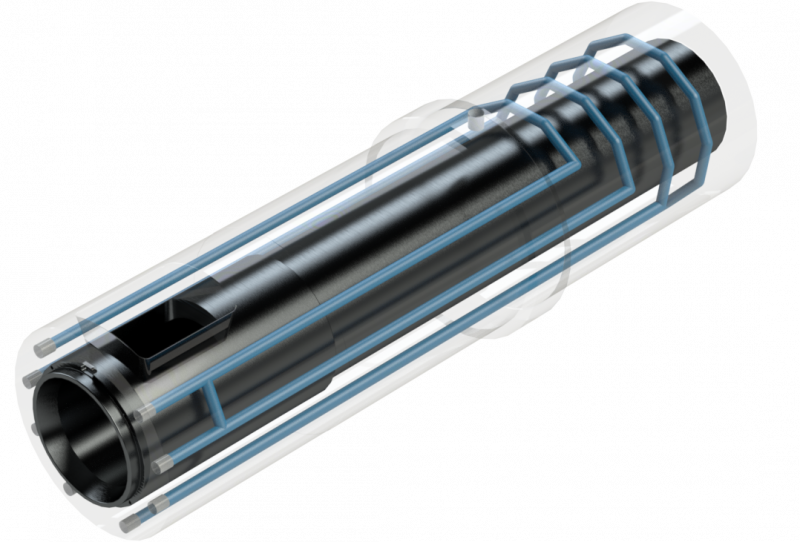

Especially when it comes to medium and larger sleeve dimensions, cooling the sleeve minimizes temperature difference between various parts of the sleeve, resulting in less dimensional deformation.

In most cases finding an optimal ratio between cooling circuit positioning, sleeve thickness and assembly tolerances minimizes the warpage effect.

Using thermoregulated sleeves, casters expand the lifespan of both, the sleeve and the piston, but eventually, the wear of the nitration layer leads to sleeve replacement.

Replacing the sleeve causes long production stoppages and is costly, so there is a constant effort on how to increase the life span of the sleeve and bring down the cost of new sleeves.

Thermoregulated Shot Sleeve

Thermoregulated Sleeve with Integral Insert / Liner

In this case, the shot sleeve is bored to form an envelope and a special integral insert/liner which covers the whole length of the sleeve gets inserted into the envelope. As the sleeve never comes into direct contact with molten alloy, sleeve replacements are completely avoided.

Thermoregulated sleeve with integral insert/liner is often referred to as the win-win solution because on one hand the costs of inserts are lower than the costs of the sleeve and on other, some of the inserts available on the market also have a longer lifespan than conventional sleeves.

Thermoregulated Envelope with Integral Insert / Liner

As depicted below, the difference in usage between integral insert/liner and the conventional shot sleeve is that cost of envelope occurs only once, when integral insert solution is implemented and then, for each next replacement, only the insert/liner needs to be changed with a new one, while envelope remains unchanged.

Each of the discussed solutions brings sleeve lifespan improvement compared to the standard combination of steel plunger and sleeve without thermal regulation, however, the most cost-effective one is the usage of the thermoregulated envelope with integral insert. Using it eliminates

the need to replace the sleeve, enables optimal hardness of the insert and that results in an increased lifetime, as well as the lower frequency of production stoppages. Integral insert/liner is designed to be replaced quickly and with ease.

In the below text we will take a closer look at HTS IC Thermoregulated envelope with integral insert; currently, the most efficient solution on the market and the benefits its usage brings to the die caster.

HTS Integral Insert / Liner

HTS integral insert/liner is a patented solution for sleeve cost optimization developed by HTS IC company Alrotec Technology. There are two main factors that make HTS integral insert outperform other solutions available on the market; production technology of the insert/liner and own, especially developed alloy used to produce the insert/liner.

HTS Envelope with 4 cooling circuits and Integral Insert / Liner

Its usage has proven to bring certain advantages, such as:

-

longer lifetime (on average 20% – 40% compared to conventional 1.2343 sleeves)

-

lower frequency of shot sleeve replacements

-

shorter production stoppages (quick replacement)

-

substantially lower overall sleeve costs

Wear Resistance

An important thing to note is that using an integral insert/liner does not influence the outer dimensions of the envelope, so in most cases, there are no changes to the existing layout required.

Another great cost advantage of integral insert/liner is, that the initial investment into the envelope can be avoided by re-machining the existing sleeve (this is mostly possible in the case of sleeves without thermal regulation, however, each sleeve should be looked upon separately).

Most often sleeves are produced using 1.2343 / H11, 1.2344 / H13 to 1.2367 tool steels and nitrided for better wear resistance.

When using an integral insert/liner, the envelope is never in direct contact with a molten alloy so it doesn’t need to be made using hot work tool steel, but can be replaced with prehardened tool steel, meaning that the cost of its production is lower compared to the conventional sleeve.

Having the envelope as a separate piece, the insert/liner can be produced focusing on lifetime increase and dimensional stability. HTS IC has developed a special alloy and production technology for integral inserts that allows reaching higher nitration layer hardness.

As seen in the graph above, in the case of HTS integral insert made with special alloy, the nitration layer reaches a hardness of 1250 HVickers. This is 25% more than in the case of 1.2343 / H11 made shot sleeve.

In order to compare the wear resistance of conventional 1.2343 / H11, 1.2344 / H13 and 1.2367 sleeves with HTS integral insert, a laboratory test in an internationally approved laboratory (Ceit Research Centre, member of Basque research & technology alliance) were carried out.

Samples of tested materials were compared in terms of linear dimension loss when exposed to conditions harsher than in-service.

Each of the samples was rotated in an aluminium bath at 800C, at 240 r.p.m. for 3 h in order to additionally accelerate the wear.

1.2367 Specimen wear measurement

Wear test results

| Steel Grade | Material Loss |

| 1.2343 (H11) | 3.000 |

| 1.2344 (H13) | 2.500 |

| 1.2367 | 1.800 |

| HTS IC alloy | 400 |

Laboratory test has indicated that combination of specially developed HTS alloy and harder nitration layer results in 87% less wear, compared to conventional 1.2343 / H11 made sleeve.

In-service performance

Several combinations were implemented in a real production environment of one of the largest EU based die casting companies. All of the combinations were tested on the same production line with a 120mm plunger and constant casting parameters, to ensure as comparable results as possible.

Following solution combinations were tested:

-

Conventional sleeve made with 1.2343

-

Thermoregulated sleeve made with 1.2343

-

Thermoregulated envelop with an integral insert made with 1.2343 steel

-

Thermoregulated envelop with an integral insert made with 1.2344 steel

-

Thermoregulated envelope with an integral insert made with special HTS developed alloy

When comparing thermoregulated sleeve without insert and envelope with 1.2343 / H11 integral insert, the number of shots before the first replacement was 4% higher, because integral insert has higher hardness than the sleeve without insert (50.000 shots compared to 48.000 shots).

After replacing the 1.2343 / H11 insert with an insert that is produced from specially developed alloy and has a 25% harder nitration layer, the number of shots before 1st replacement has increased substantially, by 70%.

Cost efficiency

Lower envelope production costs, extended integral insert lifetime and eliminated need for sleeve replacement all directly result in lower costs for the die caster.

Below are two different examples from HTS IC customers, comparing the two options:

- thermoregulated sleeve without integral insert

- combination of thermoregulated sleeve and integral insert