innoSleeve Insert implementation

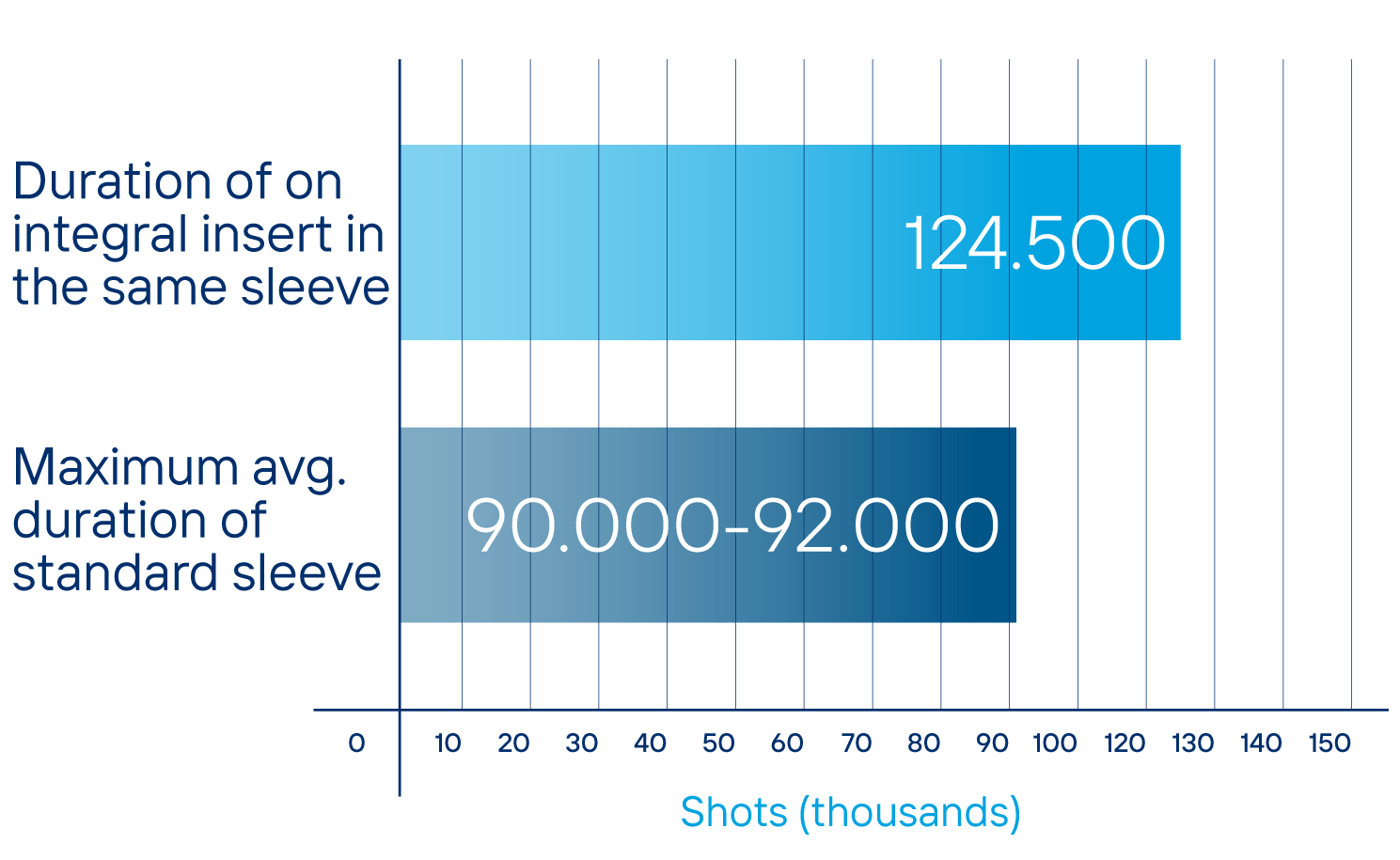

In terms of constant process optimization efforts, ZML was looking for an option on how to further optimize the cost efficiency of the shot sleeves. HTS as a long-term partner and supplier of various components to ZML, suggested the usage of innoSleeve insert, as, according to our experience, it results in a longer lifespan than conventional sleeve and reduces the production downtime related to replacement stoppages.

38%

longer sleeve lifetime

Background

Gruppo Cividale finds origin in Acciaieria Fonderia Cividale, near Udine, in the end of the '60s. Thanks to a continuous process in production and plant rationalization, Gruppo Cividale has become one of the leading European producers in steel and cast-iron castings, aluminium castings and forgings. Plant Investments make it possible to consolidate the technological leadership in the energy, mechanical, construction, automotive components and home appliances markets. As of today, ZML operates 17 die casting presses up to 2.500 t.

Process/Implementation

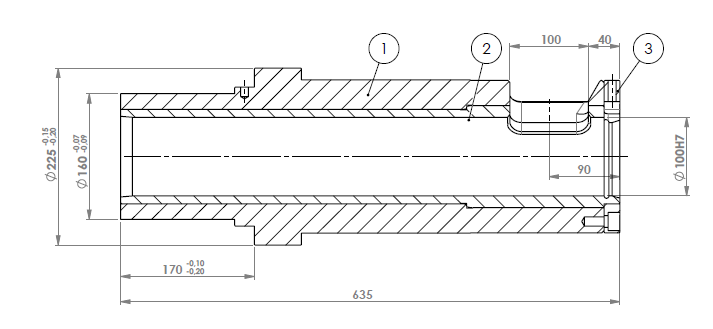

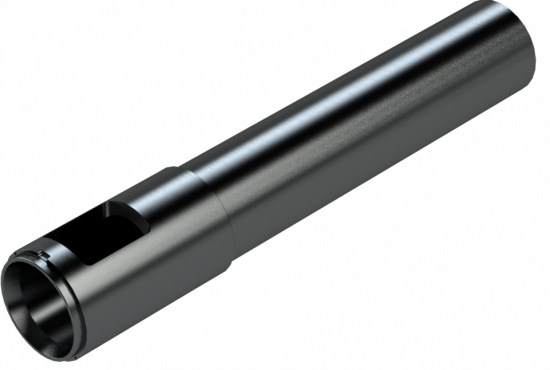

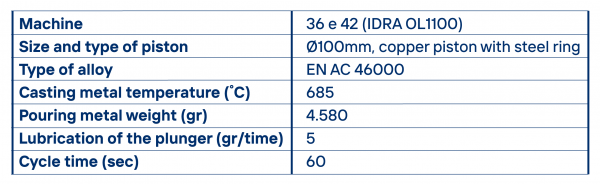

Based on potential savings and lifetime extension, ZML production team decided to trial the HTS innoSleeve insert on a Ø100mm IDRA OL 1100 line.

Table 1: Process parameters on trial production line

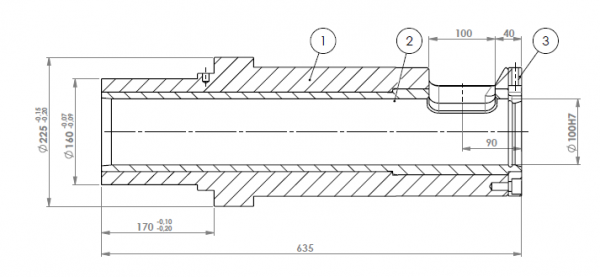

To implement the innoSleevel insert, an existing sleeve without thermoregulation was re-machined. This way it was possible to recover a shot sleeve to be scrapped and further improve the cost-efficiency. As the insert fixing system guarantees the same total length measurement (635mm) as the standard one, it was therefore not necessary to change the machine parameters to use this solution.

Prior to implementation a checklist we provide for each project was followed by ZML production team and HTS technical support team, in order ensure a smooth implementation and a successful trial.

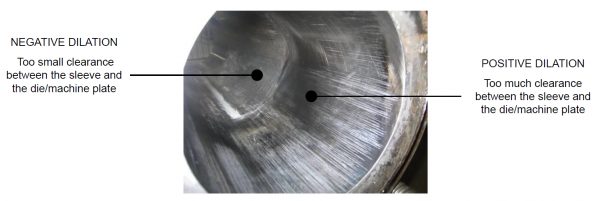

1. Check the machine alignment by measuring the distance from the piston rod to the internal diameter of the shot sleeve

a) at the loading stage

b) at the solidification stage

2. Check the lubrication amount

At the beginning of the process minimum of 3 to 5g should be applied. Later this amount can be reduced according to the manufacturer's recommendation. Based on the shot sleeve specifications the lub-drop system is sufficient.

CONSTANT COMMUNICATION

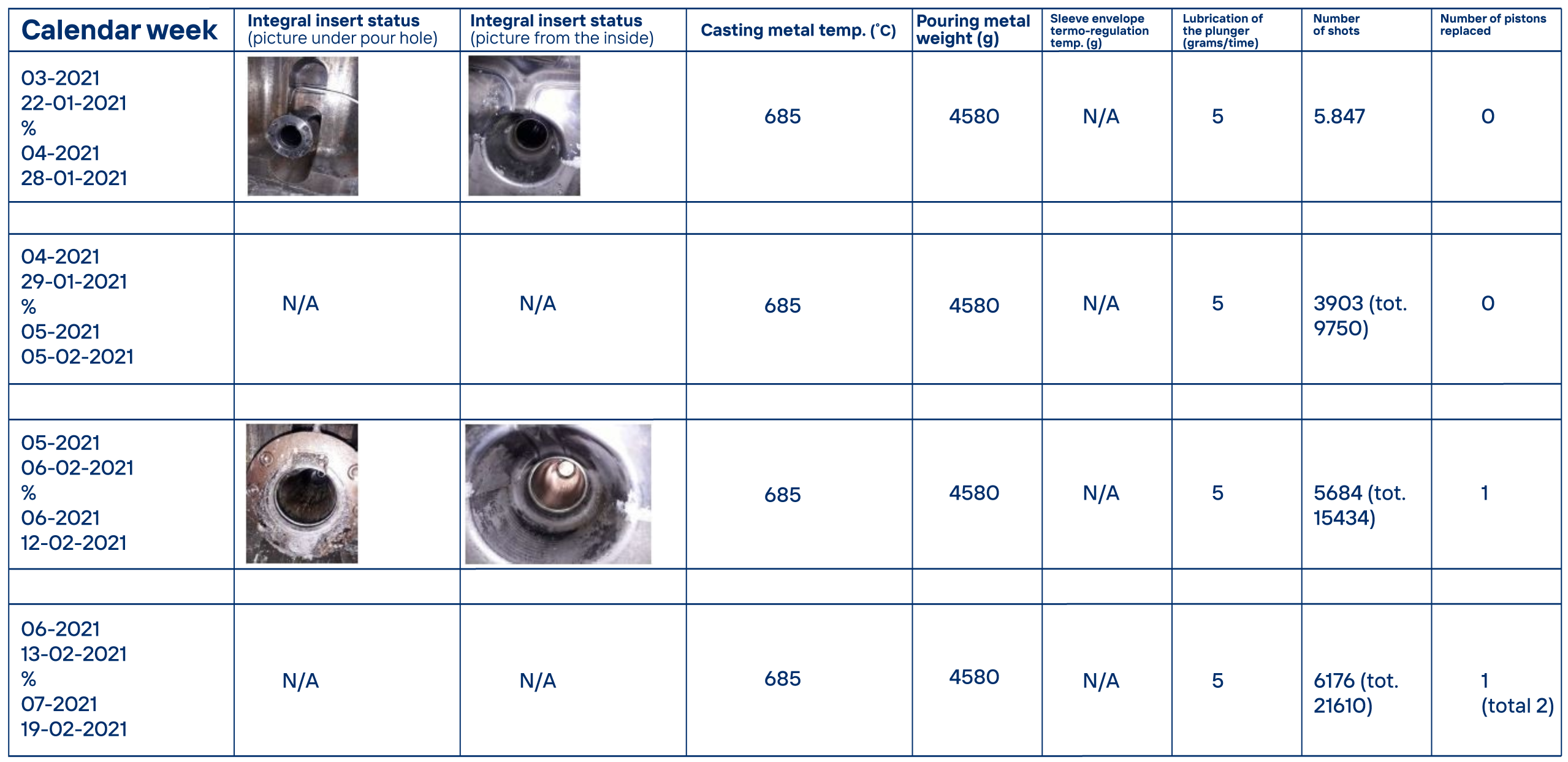

During the trial, ZML and HTS teams were in constant contact, making sure that all the process parameters and other factors are within the acceptable range. The performance of innoSleeve insert was measured and followed weekly, through a simple report.

RESULTS OF THE INNOSLEEVE INSERT TRIAL

The shot sleeve has reached a total life of 124.500 shots. The total number of pistons consumed was 15, resulting in average piston life of 8.300 shots.

An increase of 0,25mm on the front diameter was detected, which would have allowed extending the life. However, under the pour hole, worn areas deeper than 1mm were noted.

Based on this reason, the innoSleeve insert trial was terminated to avoid a potentially exponential increase in piston wear.

Following the positive outcome of the test, ZML proceeded with a second step. A second insert was built to replace the previously worn one.

A second sleeve with the same dimension as the first has been modified with the integral insert.

Two other types of sleeves were identified to extend the test on the 1.300tons machine (piston diameter 100mm) and 1.600tons machine (piston diameter 95mm) where trials are currently being carried out.

Roberto Tomasella - ZML Engineering and tooling department

"If the result of the second step will be as positive as the first, we have already identified other types of sleeves where to adopt the same solution:

The first type is a sleeve that has a total length of 705mm, with a Ø100mm piston, to be used on 1100-1350tons machine.

Finally, the same type of sleeve used for the first test could be reused, building an insert with an internal diameter of 95mm.

It would allow us to have different diameters (95mm or 100mm) using the same sleeve."

For the implementation of the integral insert an existing sleeve without thermoregulation was re-machined. This way it was possible to recover a shot sleeve to be scrapped and further improve the cost efficiency. As the insert fixing system guarantees the same total length measurement (635mm) as the standard one, it was therefore not necessary to change the machine parameters to use this solution.

Prior to implementation a checklist we provide for each project was followed by ZML production team and HTS technical support team, in order ensure a smooth implementation and a successful trial.

- Check the machine alignment measuring the distance from the piston rod to the internal diameter of the shot sleeve:

) at the loading stage

b.) at the solidification stage

Measurement should be taken in the cold and warm environment.

- Check the lubrication amount. At the beginning of the process minimum 3 –5g should be applied. Later this amount can be reduced with manufactures recommendation. Based on the shot sleeve specifications the lub-drop system is sufficient.

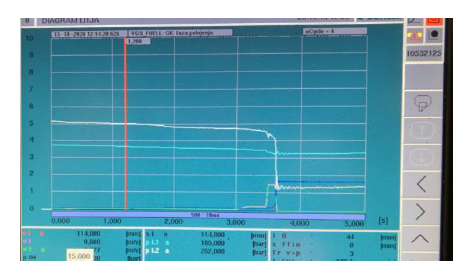

- Depending on the machine used, follow the pressure diagram for troubleshooting

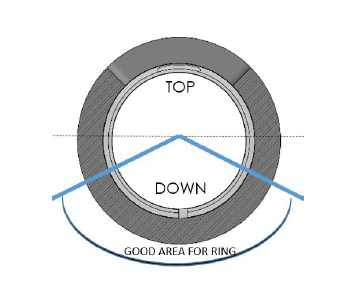

- When using a piston with ring system, make sure that the cut of the ring is not facing the pour hole. In the attached picture you can see a good area for the piston ring cut.

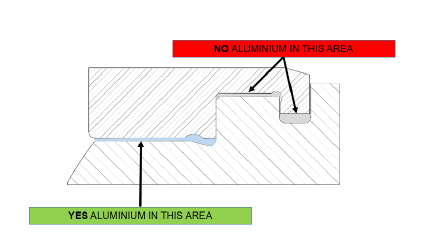

- When using a piston with ring system, make sure Aluminium is not collecting in the ring holder groove

- When using a piston with ring system, check the tablet to see if flash is forming. This is an indicator of a stable process.

- Follow signs of wear on the integral diameter of the sleeve for troubleshoot