on series of 4 sleeve replacements

innoSleeve

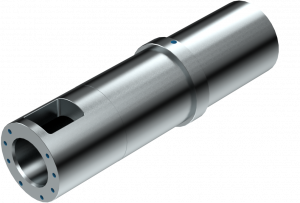

We, at HTS have developed a special shot sleeve with a substantially longer lifetime – innoSleeve.

It is used with a quickly replaceable integral insert/ liner that extends sleeve lifetime and minimizes production downtime.

innoSleeve is compatible with all iTherm® Die-Casting Injection Systems and standard Injection Systems.

HTS DIFFERENCE

As of 01.07.2023, we, at HTS have committed to the production of die-casting shot sleeves that generate up to 70% less CO2. We have decided on this important, sustainable future-oriented step, as the first shot sleeve producer in the industry. This way we are supporting our die-casting customers’ efforts to decrease their environmental footprint. To mark this significant decision, we have launched a new shot sleeve brand, called the innoSleeve.

WHAT IS INNOSLEEVE

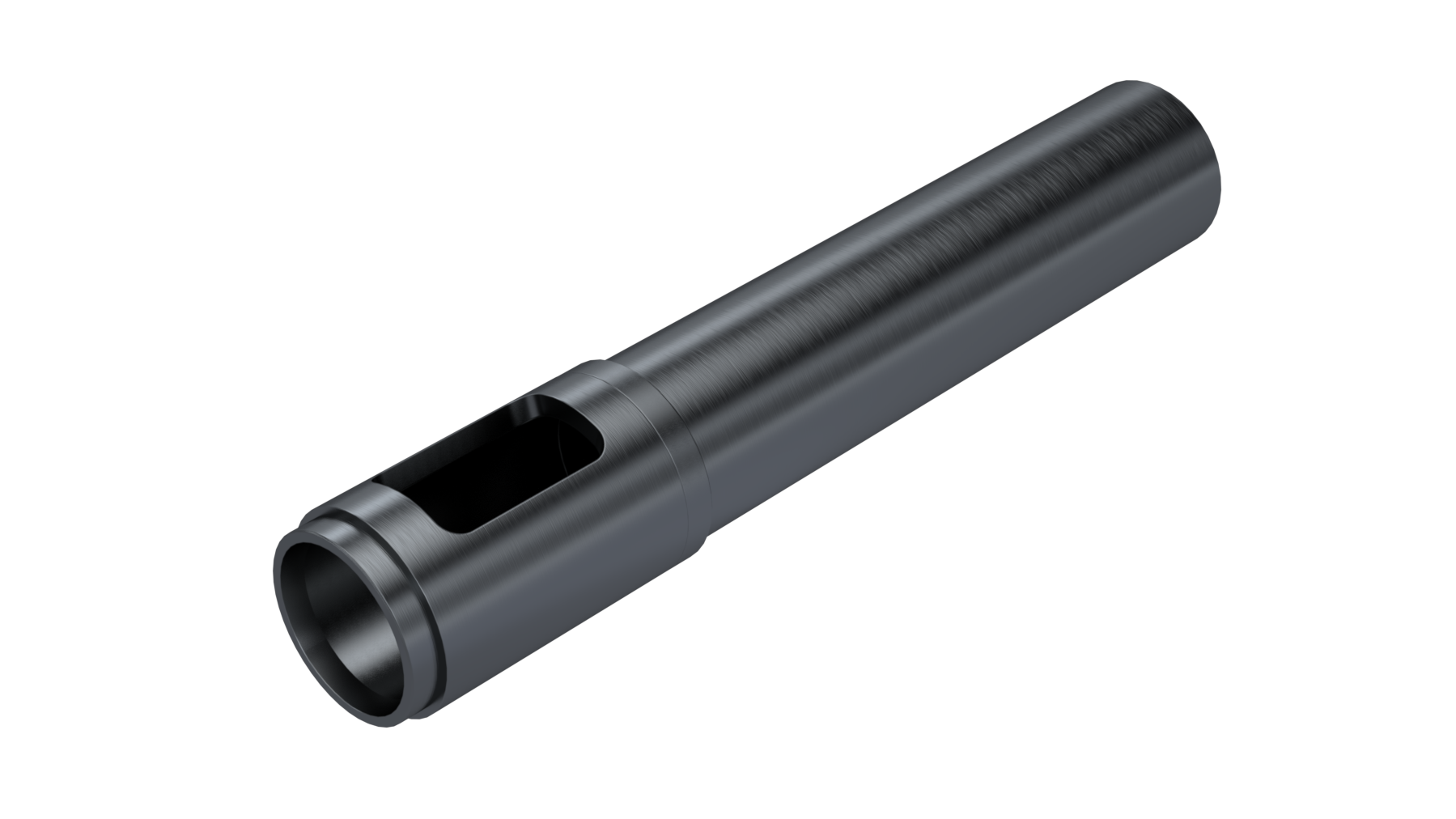

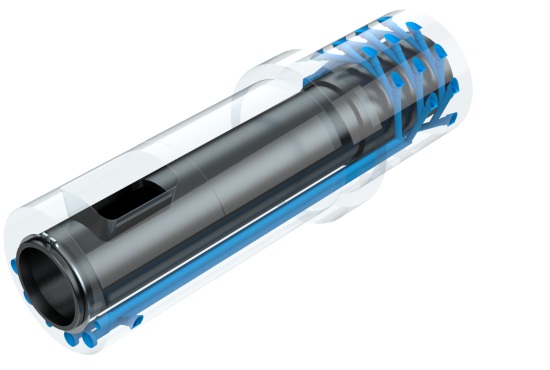

innoSleeve is used with a replaceable integral insert/liner.

It is a patented solution for sleeve cost optimization developed by HTS Technology Group company - Alrotec Technology.

A special liner is used as a lining, inside of the sleeve but it doesn‘t influence the sleeve outer dimensions.

Liner is a single-body HPDC component made of a special in-house developed alloy that extends its life substantially.

innoSleeve is compatible with all iTherm® Die-Casting Injection Systems as well as with all other Injection Systems.

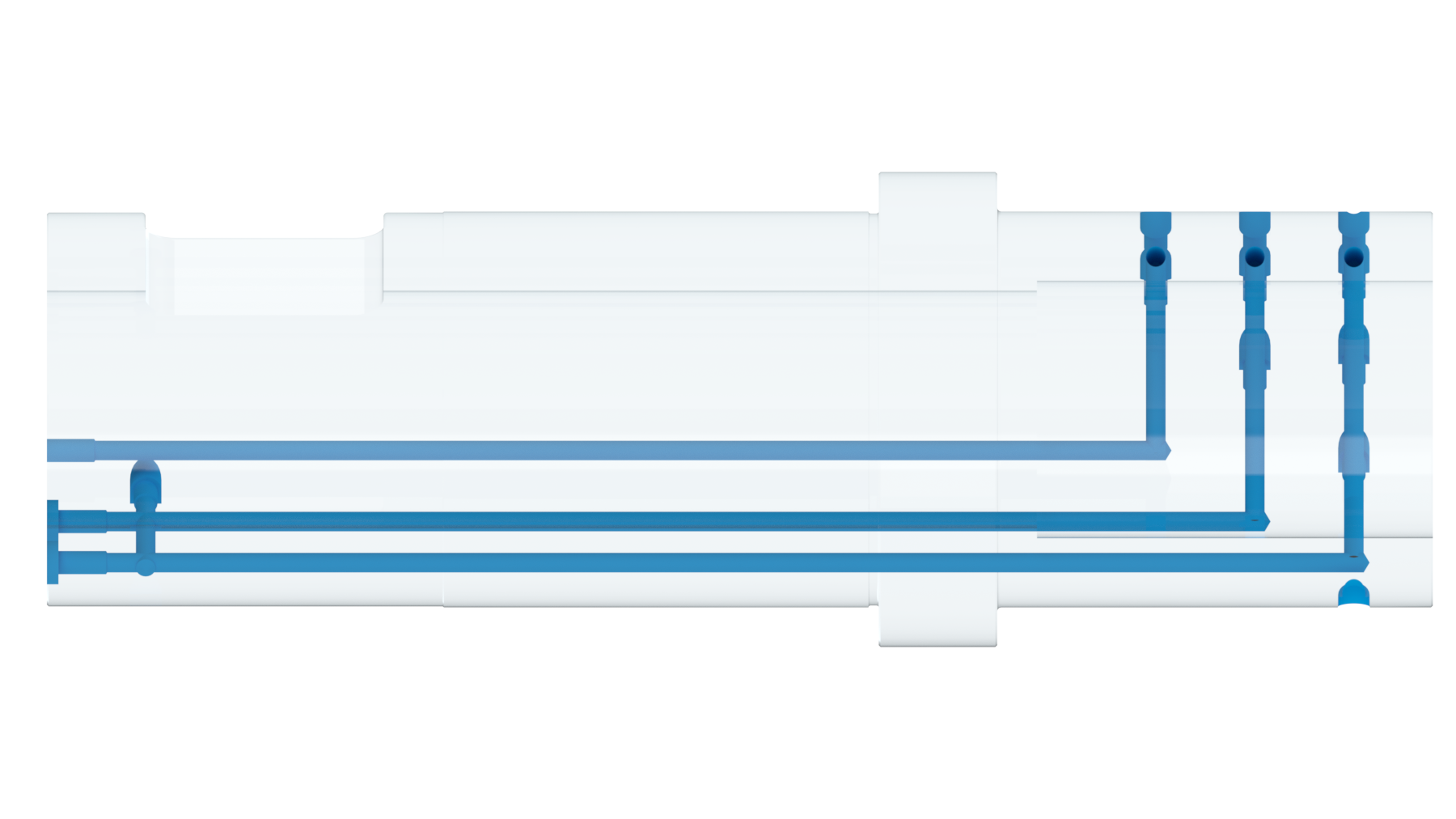

Thermal regulation

innoSleeve is available with various options for thermal regulation.

-

At the bottom of the sleeve with an interconnected system of holes preventing sleeve warpage and minimizing erosion.

-

Around the shoot end of the sleeve using a specially designed cooling ring providing additional cooling of the biscuit.

PARAMETERS

Dimensional range

Inner diameter 2 - 9 ¹/₁₆ inch (50 - 230 mm)

Length 8 - 63 inch (200 - 1.600 mm)

Lubrication

Depending on operation requirements, shot sleeve can be adjusted for various lubrication options

-

Lub drop

-

Combi lub

-

Tube lube

-

Groove lube

Material

innoSleeves are made using forged or rolled tool steel blocks produced in EU.

Integral inserts can be made of three different material choices, 1.2343 / 1.2344 or by using one of the two specially developed tool steel grades.

Delivery condition

heat treated

hardness between 42 and 50 HRC

machined to final dimension

nitrided