Blagovne znamke

HTS TECHNOLOGY GROUP

HTS Technology Group is our corporate brand, representing a unique vertically integrated business based on advanced manufacturing technologies and intensive R&D. The essence of our integration is that we bring together the know-how and experience of in-house production processes, from cutting the steel to machining, heat treatment to advanced additive manufacturing processes.

All companies of HTS Technology Group use HTS logo as a part of their name, displaying our commitment to the highest technology and manufacturing standards across the complete value chain.

iTherm®

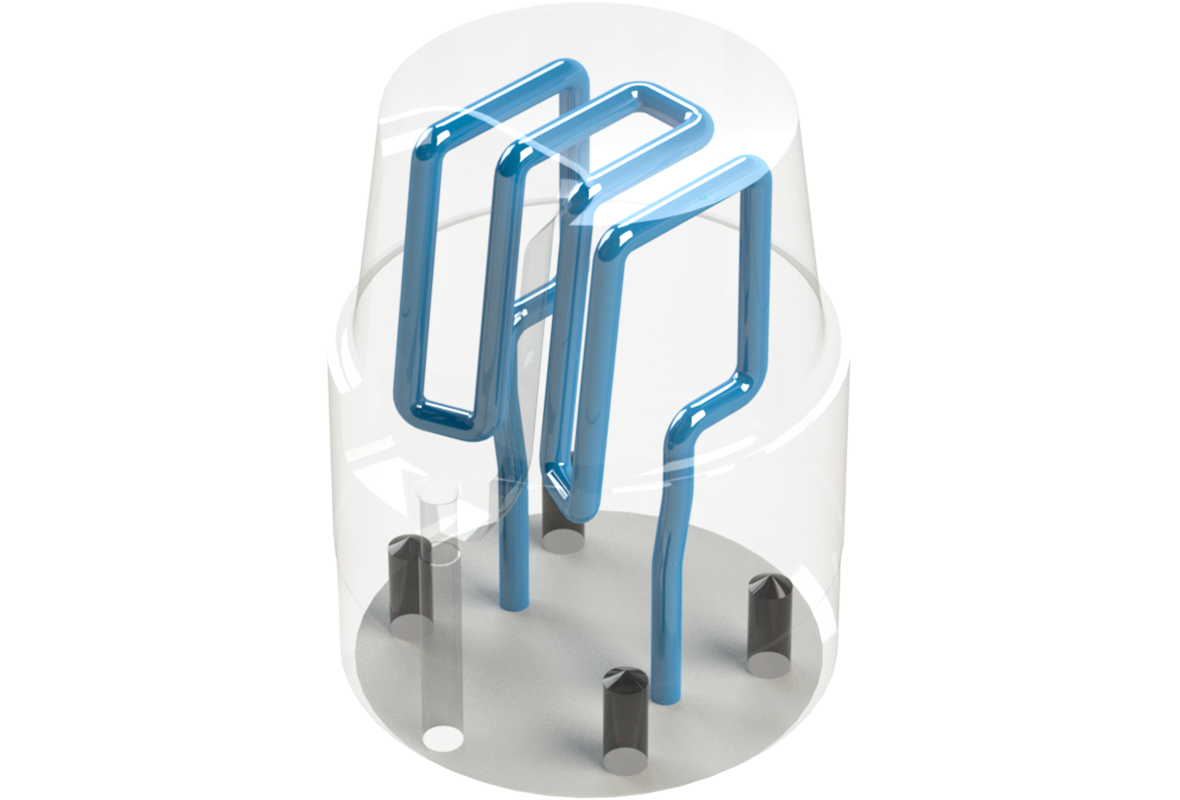

iTherm® brand stands for ultimate productivity solutions, based on principles of conformal cooling. iTherm® components are made using different additive manufacturing technologies, among which also MFT, our proprietary metal fusion technology.

iTherm® is not only a brand but also a promise, a promise of superior thermal management possibilities and unrivalled component performance.

iTherm® products are used in industries where effective thermal management of components is essential for productivity and quality. Below is an overview of iTherm® product range.

MFT™

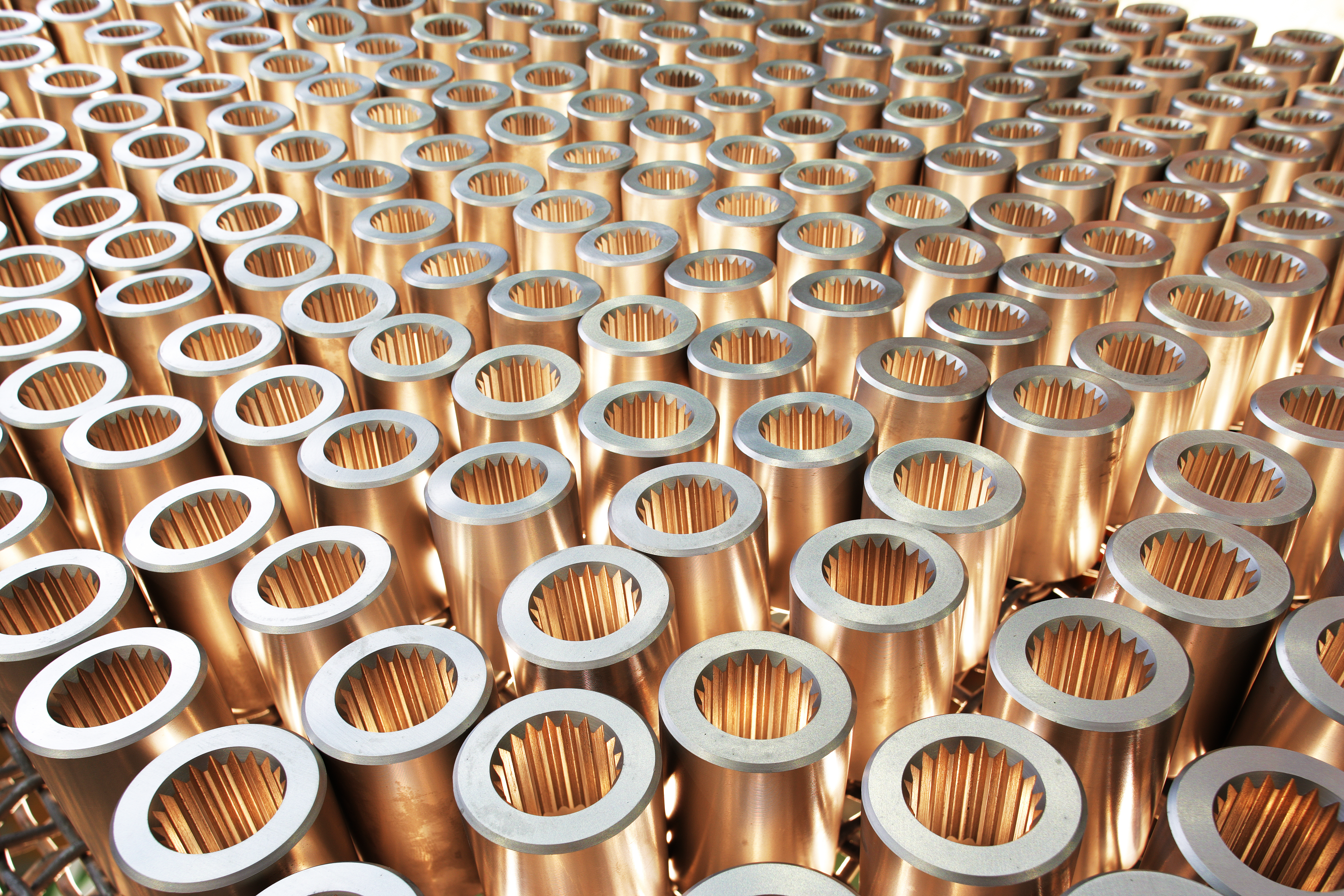

MFT™ is our proprietary additive manufacturing technology, based on diffusion bonding of pre-machined layers of premium tool steel. Mechanical properties of the diffusion bond are comparable to those of forged tool steel block.

Material selection can practically be any tool steel, although most often 1.2343 / H11, 1.2344 / H13, 420SS, High Thermal Conductivity Steel (HTCS) is used. MFT™ also enables complex geometry possibilities, such as perfect 90-degree overhangs, embedded copper pins and embedded sensors, for example.

OXIMAX®

Oximax ® is our brand for advanced surface treatment. It enhances the component's or part's surface with a 5 μm black oxide layer (Fe3O4) improving its sliding properties, wear and corrosion resistance.

It is used extensively in the automotive industry, while from the perspective of HTS Technolgy group's product portfolio, it is mainly used for die casting injection system components that are in direct contact with molten alloy.

NITOP®

Nitop ® brand represents a family of different gas nitriding and nitrocarburising treatments. From nitriding - diffusion zone of selected thickness with no compound layer, with the presence of thin and ductile “gamma prime” compound layer and with hard “epsilon” compound layer, to nitrocarburising - compound layer with high epsilon content.

PLAZNIT®

Plaznit ® brand represents a family of different plasma nitriding and nitrocarburising treatments. From nitriding - diffusion zone of selected thickness with no compound layer, with the presence of thin and ductile “gamma prime” compound layer and with hard “epsilon” compound layer, to nitrocarburising - compound layer with high epsilon content.